|

Specifications |

|

|

Model |

GS-LFTP3015/4015/6015 |

|

Output power of laser source (Optional) |

500W/1000W/1500W |

|

Cutting area (L * W) (Optional)

|

3000 * 1500 mm 4000 * 1500 mm 6000 * 1500 mm |

|

Max. tube diameter |

200 mm |

|

Max. tube processing length |

3 m |

|

Max. tube cutting thickness |

6 mm |

|

X axle stroke |

3048 mm |

|

Y axle stroke |

2000 mm |

|

Z axle stroke |

80 mm |

|

Cooling |

water cooling |

|

Max. accelerated speed of X, Y axles |

1.2 G |

|

Kerf Width |

0.1 - 0.3 mm |

|

Positioning accuracy of X, Y and Z axles |

± 0.05 mm |

|

Repeated positioning accuracy of X, Y and Z axles |

± 0.03 mm |

|

Processing precision of work piece |

± 0.1 mm |

|

Kerf harshness |

Ra 3.2 - 12.5 μm |

|

Voltage |

380V, 50/60Hz |

|

Continuous working time |

24 Hours |

|

Max. bearing weight of working platform |

600 Kgs |

|

Total installed capacity |

20 - 25 KVA |

|

Total protection level of power supply |

IP54 |

Description

Advanced fiber laser cutter

◎ Smaller Focal spot and cutting gap. Much more efficient and better processing quality.

◎ Extremely high cutting speed which equals to two times of tradition CO₂ laser cutting machine with same power specification.

◎ Adopt international top brand laser source with stable performance.

◎ The photoelectric conversion rate is three times higher than traditional CO₂ laser cutting machine, and it’s environmental protection.

◎ Lower running cost compared with traditional CO₂ laser cutting machine, the power consumption is 20%-30% of CO₂ laser cutting machine.

◎ The maintenance cost of fiber laser cutting machine is much lower since it’s without reflective lenses.

◎ Convenient operation with fiber transmission, laser route adjustment is unnecessary.

◎ Satisfied with flexible processing with small size and intense structure design.

◎ Gantry design with double drive structure, high damping machine tool with better rigidity which can stand higher speed and acceleration speed.

◎ Adopt with imported AC server motor system and transmission system to ensure the high speed, high precision and high reliability.

◎ The rack and guide is comprehensively sealed to prevent the friction without oil and dust pollution in order to make the drive system much longer service time and ensure the movement precision of the machine tool.

◎ Professional CNC laser control system with computer control which is more simple and convenient for operation.

HAN’S GS CNC SYSTEM

Our Ahead Techs CNC system for laser cutting from US is on base of PC control technology. The system ensure the high dynamic properties with movement control software and hardware, adopting field bus technology. It can transform the cutting power to cutting speed and efficiency in most degree. The Ahead Techs CNC system provide professional cutting function including track control, leapfrog cutting, power control, gantry axle control and etc.

Why it’s EtherCAT ?

Why we choose EtherCAT ?

1.Similarity: soft motion control + EtherCAT software host station, independent to hardware

2.Abundant servo and IO product choice

Soft motion + EtherCAT Bus = Open motion control platform

ENC Ahead namely EtherCAT NC Control is CNC system based on PC Open Bus issed by AheadTechs Inc in 2014

Properties

Công ty chúng tôi rất hân hạnh được phục vụ quý khách hàng .

Địa chỉ : Số 2010 -CT3A - KĐT Văn Quán - Hà Đông - Hà Nội.

Địa chỉ kho máy: Số 18BT4-1, KĐT.Trung Văn, Nam Từ Liêm, Hà Nội.

Tell : 04 35666727 - 0912666817 - 0912817066.

Website: maylaserhn.com- vinco.com.vn

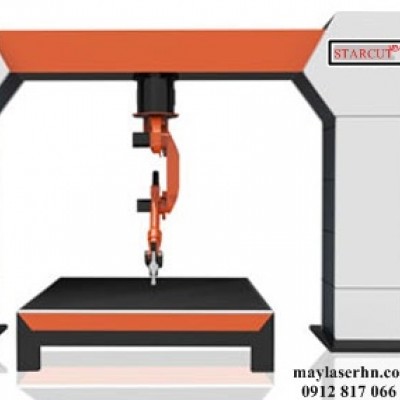

Máy Laser Fiber Starcut ST18-HF

Liên hệ

Single Drving Fiber Laser Cutter

Liên hệ

Máy Laser Fiber Starcut ST-FBR

Liên hệ