Laser roll to roll textile fabrics continuous engraving. Germany 3D dynamic Galvo system, finishing continuous engraving marking in one step.“on the fly” mode engraving technology. Suitable for large format fabric, textile, velvet, denim engraving, greatly improving fabric processing quality and added-value. 500W CO2 RF metal laser tube (standard configuration), fast processing speed and fine results.Red light positioning device, accurate material feeding.

-160LD-ZJJF.jpg)

Roll to Roll Fabric Laser Engraving Machine ST(3D)-160LD-ZJJF

• For textile fabrics continuous engraving. Width of working table is up to 1600mm.

• Germany 3D dynamic Galvo system, finishing engraving, punching and cutting in one step.

• Adopting “on the fly” mode engraving technology, laser engraving while material moving, fabric no need to stop.

• Suitable for large format fabric engraving, greatly improving fabric processing quality and added-value.

• 500W CO2 RF metal laser tube (standard configuration), fast processing speed and fine results.

• Red light positioning device ensures accurate material feeding.

• 5-inch LCD screen operating system. Supporting multiple modes of data transmission. Enabling offline or online operation.

-160LD-ZJJF%202.jpg)

-160LD-ZJJF%201.jpg)

|

Standard Configuration |

|||

|

auxiliary ladder |

automatic deviation rectifier |

fixed top exhaust suction system |

automatic feeding and rewinding |

|

ST(3D)-160LD-ZJJF Roll to Roll Laser Engraving Machine |

|||

|

Laser Generator and Optic parameters |

|||

|

Laser Type |

CO2 RF metal laser |

Laser Power |

500W / 300W |

|

Laser Wavelength |

10.6 micro meters |

Galvo process area |

1600mmX1600mm |

|

Galvo process speed |

0-10000mm/s ( Speed varies from processed material, graphics and processing requirement) |

||

|

Positioning Accuracy |

±0.1mm |

||

|

Motion System |

Offline mode Servo motor control system, 5-inch LCD screen |

||

|

Power Supply |

AC380V±5% |

||

|

Software system |

|||

|

Control software |

Goldenlaser original software |

||

|

Software Format |

BMP, AI, DST, DXF,PLT, etc. |

||

|

Working table parameter |

|||

|

Working table type |

Engraving conveyor working table |

||

|

Conveyor table motor |

Servo motor |

||

|

Assistant System |

|||

|

Protection System |

Full protection with optic part structure |

||

|

Control System |

GoldenLaser III control card |

||

|

Cooling System |

Constant temperature water chiller |

||

|

Exhaust System |

Fixed upper exhaust suction system (Filter system optional) |

||

|

Standard Collocation |

Auxiliary ladder, Red light positioning, roll to roll feeding and rewinding (Servo system, position correcting device) |

||

|

***Note: As products are constantly updated, please contact us for latest specifications. *** |

|||

Roll to Roll Laser Engraving Machine Application

Suitable for engraving, marking cutting, punching, hollowing garment fabric, home textile, denim jeans, flannel fabric, suede fabric, cloth, woolen fabric, leather and more flexible textile fabric materials

Laser Galvo Engraving System for Textiles Processing Industry

WHY LASER FOR TEXTILES MARKING INDUSTRY?

Compared with traditional PRINTING or DYEING, laser has its advantage to lead in the textiles industry development.

|

Design |

Mould |

Added value |

Process |

Maintenance |

Environment |

|

|

Laser engraving |

Any personalized |

No need |

5-8 times |

One time process, |

Almost no consumable parts, free of maintenance |

No pollution |

|

Dyeing & Printing |

Simple and Trite |

High cost |

2 times |

Complicated process, |

Expensive dyestuff and ink |

Chemical pollution |

ZJJF(3D)-160LD TEXTILES Laser Engraving System Introduction

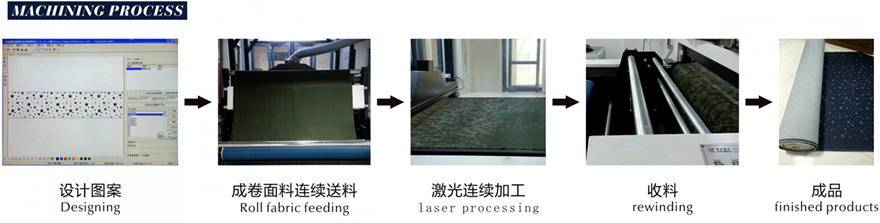

The Working Flow Profile (ROLLS TO ROLLS FLYING MARKING GALVO SYSTEM)

Feeding station with auto-feeder system → 3 axis dynamic galvanometer processing station → rewinding system station

-Auto-feeding system with automatical rectification function, ensures the feeding along with the same straight line.

-The Patented exhaust system ensures the exhaust effect of large working size to be completely taken away the smoke.

-Human-based design with the lift, convenient for adjusting the galvo mirror and maintenance.

-Control panel with detailed function, no need computer control.

LASER SOLUTION OF TEXTILES ENGRAVING

How to separate apart from homogeneous competition, how to increase the added-value and improve profits, Golden Laser launched a series of fabric engraving and hollowing solution:

Combine high-tech and traditional industries to bring personalized fashion elements;

Flying laser engraving technology used for rolls fabric;Simple operating, no need human assistance;

High efficient, high speed, high precision, high added-value, high ratio with price-performance and highly personalized process.

To meet the customers’ needs, Golden Laser is leading the industry development and innovation with fast pace of innovation and humane strategy.

Công ty chúng tôi rất hân hạnh được hợp tác và phục vụ Quý khách hàng.

Mọi thông tin chi tiết Quý khách vui lòng liên hệ:

Công ty TNHH Đầu Tư Quốc Tế Việt Nam

Đ/c: Số 18BT4-1 khu đô thị Trung Văn, Nam Từ Liêm, Hà Nội

Tell: 04 3566 6727 - 04 4450 8666 _ Hotline: 0912 817 066 - 0901 754 566

Website: maylaserhn.com - vinco.com.vn